Hot dip galvanizing

Hot galvanizing is a process during which a layer of zinc is applied to metal aggregates. This is done by immersing them in a container of melted zinc.

In the summer of 2018, a workshop was launched where metal structures are galvanized using unique and innovative technologies. For this, hot-dip galvanizing equipment is used, created by the well-known Austrian brand Ingenia. Hot galvanizing is considered a modern and high-tech method, the purpose of which is to protect metal structures from temperature changes, the appearance of various types of rust: soil, water. The use of anti-corrosion protection using the hot galvanizing method increases the wear resistance of the metal structure several times.

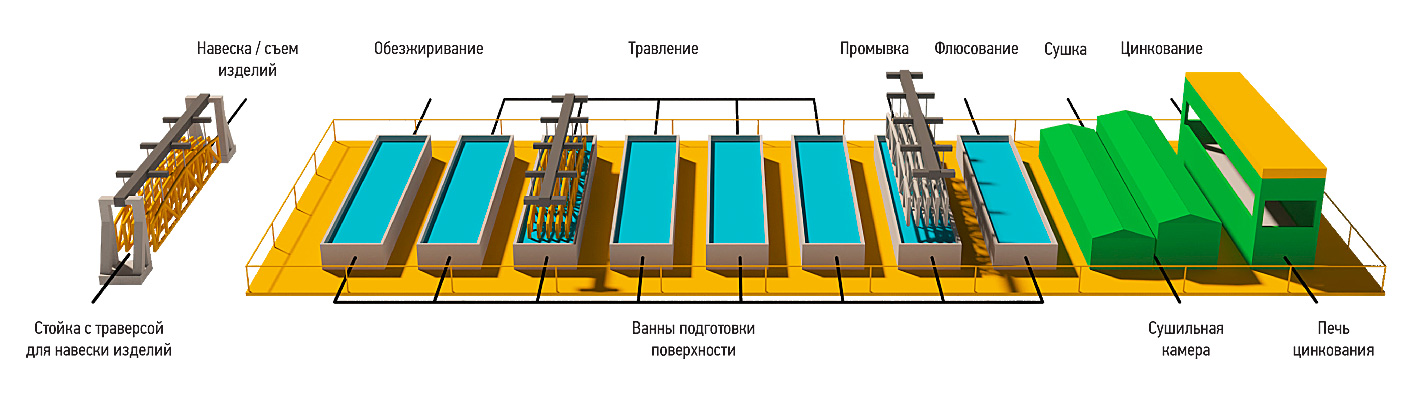

The essence of the process is to apply a zinc layer by immersing the structure in prepared molten zinc, the temperature of which reaches 450 degrees. As a result, diffusion penetration of the composition through the iron lattice is carried out. The result is a zinc coating that is not susceptible to mechanical deformation. Before immersing the structure in the composition, a phased preparation of the treated surface is performed. This happens on modern and precise equipment:

All these steps ensure the impeccable quality of the coating, the durability of the layer. It is important to note that galvanizing takes place in a Pilling brand bath, the dimensions of which are 13.5x2.2x3.5 m.

Equipment designed for hot galvanizing makes it possible to process structures whose mass should not exceed 6 tons. A coating thickness of 200 µm is created. This parameter depends on the quality of the steel, as well as the shape and dimensions of the structure. The equipment produces up to 30,000 tons per year.