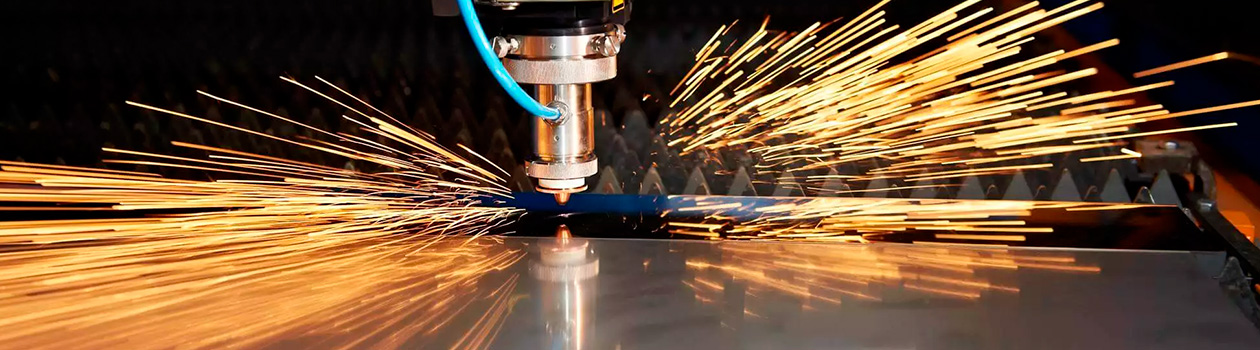

Laser cutting of metal

Metal laser cutting is a popular cutting technology that uses a laser beam. This technology allows processing rolled metal into several components. The advantages of laser cutting are maximum cutting precision and productivity. Technology makes it possible to simplify the workflow and make it easier and more efficient.

You can order cutting of stainless, brass, copper, aluminum and ordinary black rolled products from us. We have favorable rates for the range of services provided. There are discounts for corporate clients.

Features

Targeted beams make it possible to obtain elements of complex shapes and extremely sharp corners. Non-contact technique is used for processing metal of different thickness.

Laser cutting services are ordered from us for cutting the following types of alloys:

- Titanium. Pure metal has a good response to the thermal energy of the beam. The inclusion of oxygen in the composition makes it possible to speed up the processing, and at the same time, an oxide layer is obtained at the cut site, which is then eliminated by the action of oxygen.

- Aluminum. The high thermal conductivity of the aluminum raw material influences the use of the cutting machine with maximum beam precision and output from 500W.

- Copper and brass, they absorb some of the energy during cutting.

- Steel.

The action on the workpiece occurs through high temperatures.

How it works

Laser cutting of metal occurs with the use of a laser machine that sends a beam to the place of cutting. The direction of the beam is done by computer. The equipment collects a significant amount of energy at the minimum place of the metal, under the influence of which the raw material is heated and melted. After that, the billet evaporates on its own or it is blown out by the action of the gas.

During processing, there is no mechanical action on the working area, which is therefore not subject to deformation and breakage. The technique is used for cutting raw materials with low rigidity. We use equipment with fiber, gas and other lasers.

Dignity

This technology is widely used for its advantages:

- maximum precision, which allows you to get decorative and design details;

- process speed;

- economical consumption of material due to the absence of the likelihood of damage to its surface;

- smoothness of the resulting product;

- Ease of use due to work automation.

Also, the use of machine tools makes it possible to process small remnants of metal products. At the same time, the reconfiguration of the equipment takes a minimum of time, and the high productivity of the laser allows processing workpieces with high hardness.